06

2022

-

07

Company Energy Conservation and Emission Reduction Information Disclosure

Company's Energy Conservation and Emission Reduction Information Disclosure

Green Supply Chain Management Work Plan (2019-2025)

(2021Revised Edition)

In response to the national dual-carbon strategy, meeting the requirements of relevant parties for sustainable development, and effectively promoting the green transformation, energy conservation and emission reduction, and sustainable development strategy of Guangdong xintao New Materials Technology Co., Ltd., comprehensively coordinating the company's resources, through comprehensive technological innovation, process transformation, production control, energy structure adjustment and other means, achieving a high-quality development path of pollution reduction and carbon reduction, and synergistic efficiency, the company established the Guangdong xintao New Materials Technology Co., Ltd. Green Supply Chain Management Committee.

Zheng Zhao, the highest manager of the company's green supply chain management, appointed Wu Meiguo as the company's representative of green supply chain management. The main responsibilities of the representative are: to ensure the planning of effective system management activities, reasonably allocate the responsibilities and powers of various departments in the creation and operation of the green supply chain, collect and maintain evidence that the factory meets the requirements of green supply chain evaluation; ensure that the whole company improves the satisfaction of"Green Supply Chain"awareness; formulate principles and methods that can ensure the effective control and operation of the green supply chain management system; report to the highest management on the construction, operation, maintenance and performance of the green supply chain management system.

The enterprise, in the form of a company's official document, issued the "Notice on the Establishment of the Green Supply Chain Management Committee", established a green supply chain management committee group, with the general manager of the company, Zheng Zhao, as the group leader, composed of staff from relevant departments such as the production department, quality control department, personnel and administration department, technology department, procurement department, warehousing and transportation department, and sales department, and the heads of various departments perform management responsibilities.

The document also clearly proposed that the personnel and administration department be used as the specialized management department for the green supply chain, responsible for daily management affairs, and take the lead in implementing the formulation and supervision of the green supply chain management objectives.

I. Work Objectives

The specific indicators for energy conservation and emission reduction are to achieve2030carbon peak targets. The state has formulated relevant target indicators. Combining the actual situation of the company, the energy conservation and emission reduction targets during the 14th Five-Year Plan period are:

1.In terms of green risk control of suppliers, it is required to achieve a high-risk supplier ratio of0%,low-risk supplier ratio>95%;

2.In terms of green information platform construction, it is proposed to establish a complete green supply chain information platform;

3.In terms of its own green production, it is proposed2020year~2022year to achieve unitGDPcomprehensive energy consumption decreased by annually5%。

Green Supply Chain Policy: High-end product structure, low-carbon energy consumption, circular resource utilization, clean production process, green product supply, and digital production methods.

II. Work Approach

Formulate energy conservation and emission reduction policies, earnestly implement Guangdong xintao New Materials Technology Co., Ltd.'s "14th Five-Year Plan" green development plan, and integrate the green supply chain policy into the entire process of enterprise development, ensuring the implementation of the policy from aspects such as organizational leadership, institutional settings, production and operation, process management, and technological progress.

Responsible for the company's overall energy-saving related work in terms of equipment and energy procurement, technology route optimization, new technology application, energy structure adjustment, financial support, and personnel training.

III. Work Plan

1.Following the concept of green manufacturing, continue to continuously promote the construction of a green manufacturing system

The companyhot melt adhesivepays attention to improving product energy efficiency and environmental performance in the production and manufacturing design links, and increases investment in green design technology research and development.

In the production process, strictly implement national and local laws, regulations, and standards. The hot melt adhesive products produced are not energy-consuming products, and the products supplied areOriental Yuhong Group, Tsingtao Brewery Groupand other waterproof membrane and food packaging manufacturers. Improved product competitiveness.

In the green supplier management link, according to the requirements of the green supply chain evaluation index system, energy-saving and environmental protection requirements will be put forward to existing upstream suppliers, and downstream industrial chains will actively coordinate the recycling and reuse of packaging materials. Based on the "Supplier Review Control Procedure", continue to promote and improve green supplier management.

Establish a supplier training system and cooperation mechanism, and conduct annual training for suppliers.

2.Pay attention to the construction of green information platform

The company invests in the construction of an intelligent manufacturing execution system and equipment interconnectionIOTplatform, upgrade and integrateERPsystem, realize end-to-end digital collaboration from market demand to production process, and achieve high efficiency under high precision. At the same time, access to customer e-commerce systems throughSAP、SRMetc.E-Business platforms and other customer procurement platforms to achieve efficient collaboration in the industrial chain.

3.Green Production Link

Green production is an important link in green supply chain management. In the production of hot melt adhesive, not only market factors but also green needs should be considered.

Green production measures include: (1) Strictly abide by national laws and regulations, and prevent environmental, quality, and safety accidents.

(2) Optimize the process flow, process layout, and introduce high-performance equipment to improve production efficiency; formulate corresponding control procedures to reduce environmental pollution and reduce greenhouse gas emissions.

(3) Optimize the energy structure, increase the proportion of low-carbon clean energy, and reduce the proportion of non-renewable energy.

(4) Restrict the use of harmful substances, improve resource utilization, reduce raw material waste, and improve product qualification rate.

4.Accelerate the development of green logistics

In the green logistics link, due to the large transportation volume, the transportation method is crucial to reducing the carbon footprint of product transportation. The company's warehousing and transportation department will create green logistics through measures such as optimizing logistics plans, using more environmentally friendly transportation methods, and improving transportation efficiency.

IV. Specific Work Measures

1.Production process optimization and energy saving

(1) Reduce energy consumption by adjusting the stirring speed of the reactor during the refined production process and material discharge.

(2) Through intelligentMESSystem monitoring of the reactor's operation, timely alarm in case of abnormalities, and reduction of energy consumption.

2.Strengthen energy management and energy saving

(1) Conduct active energy-saving training for all staff to reduce unnecessary energy consumption.

(2) Control unnecessary waiting time during material discharge and shift handover, ensuring that finished products are discharged immediately after reaction.

(3) Continuous production, reducing idle furnace time, and avoiding heat loss.

(4) Train equipment operators to standardize operations, reduce equipment discharge time, and avoid excessive refrigeration.

(5) Incorporate air conditioning, lighting, computers, and other equipment into performance evaluations.

3.Equipment transformation for energy saving

(1) Using electromagnetic heating instead of infrared heating reduces heat loss, prevents heat radiation, and improves the comprehensive utilization of heat energy.

(2) Automation transformation of the pressure-sensitive adhesive production line saves labor, improves the product's first-pass yield and image, and enhances automation.

(3) Chillers, temperature control circulation machines, and other equipment can use variable frequency control to adjust the power used.

(4) Replace lighting with infrared or sound-activated switches.

(5) Replace high-energy-consuming motors with variable frequency motors or low-energy-consuming motors.

Convey the concept of green development to upstream and downstream suppliers and customers, covering the entire process from product design, raw material procurement, production, transportation, storage, sales, use, and disposal, which helps to improve the green development level of the entire industry.

The company will, based on the departmental level objectives proposed for the above green supply chain management objectives, decompose them to various functional departments by the Human Resources and Administration department. The decomposition work follows the principles of reasonable decomposition, clear division of labor, and reasonable and feasible indicators, effectively ensuring the realization of the company's management objectives.

Note: This revision incorporates the relevant requirements of General Secretary Xi's work on carbon peaking and carbon neutrality.

Guangdong xintao New Materials Technology Co., Ltd.

2021year10Month20Day

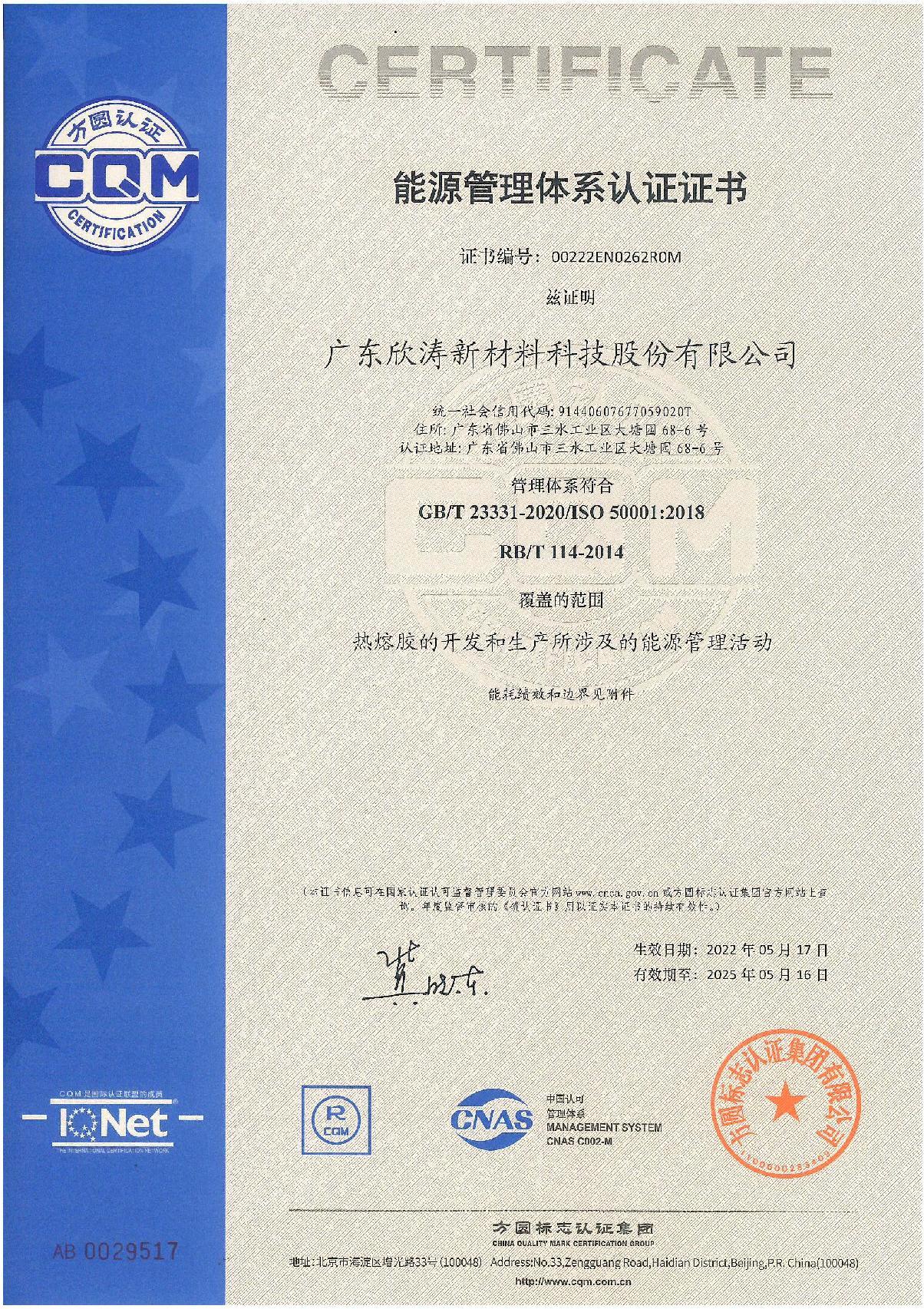

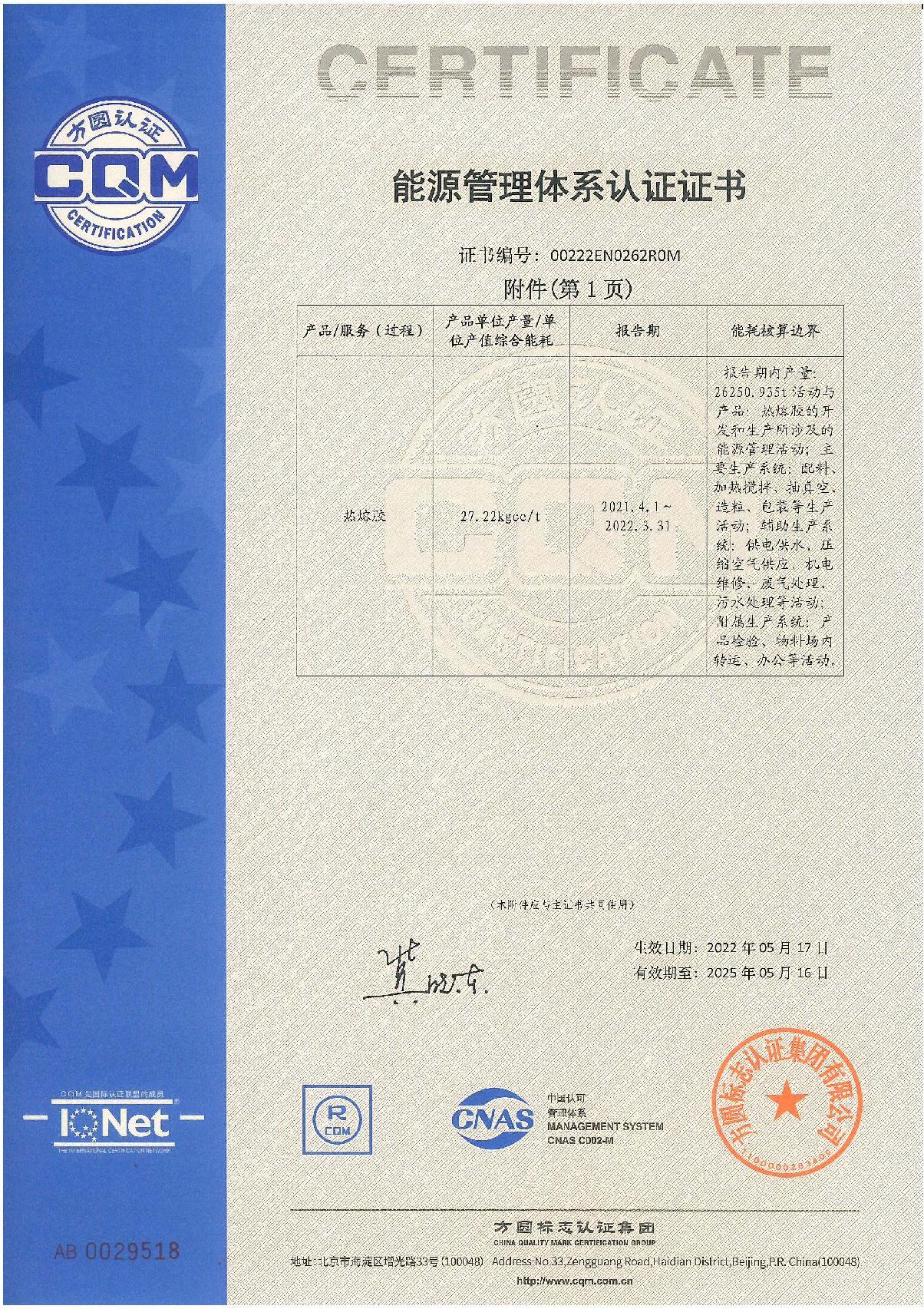

Energy Management System Certificate

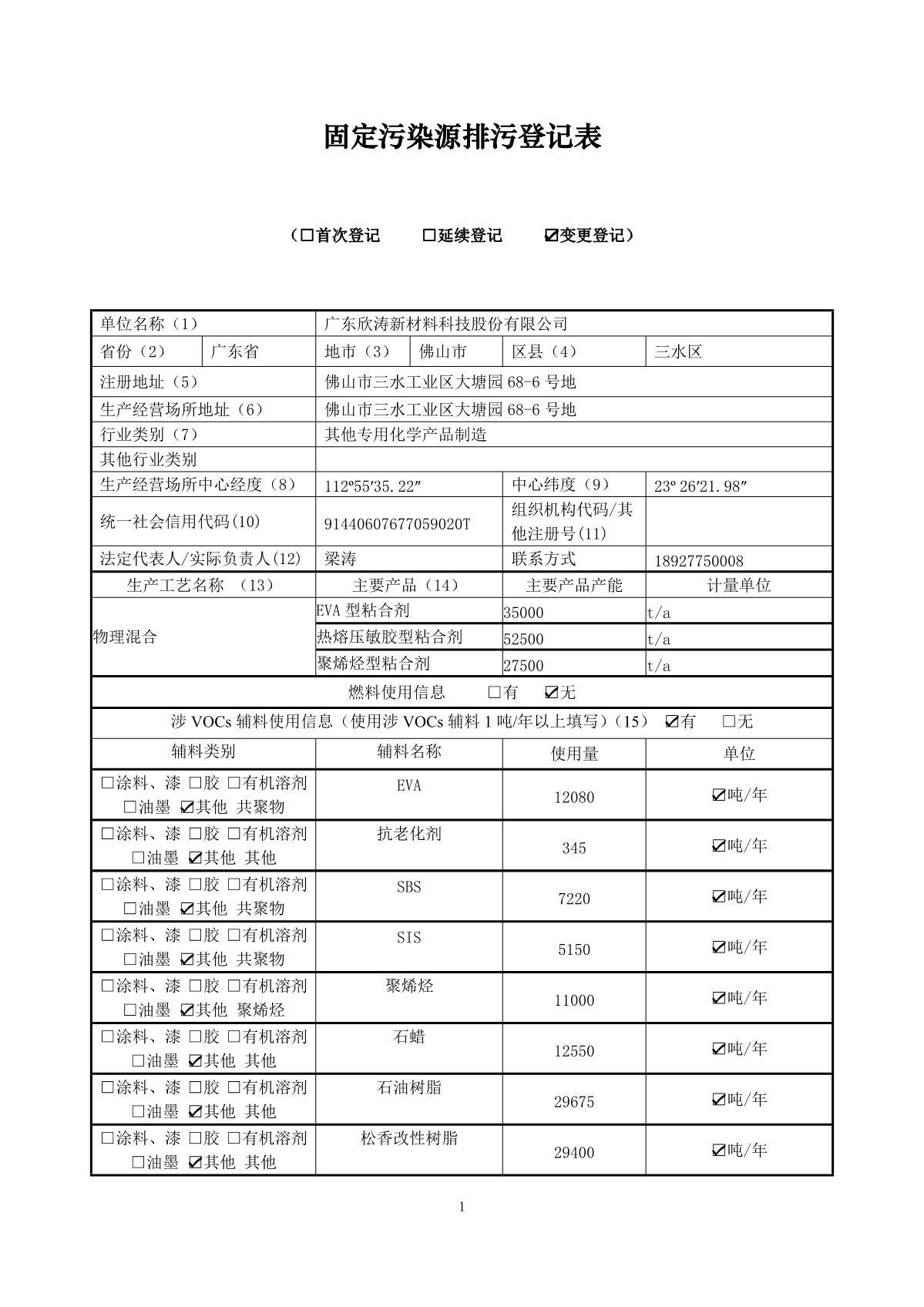

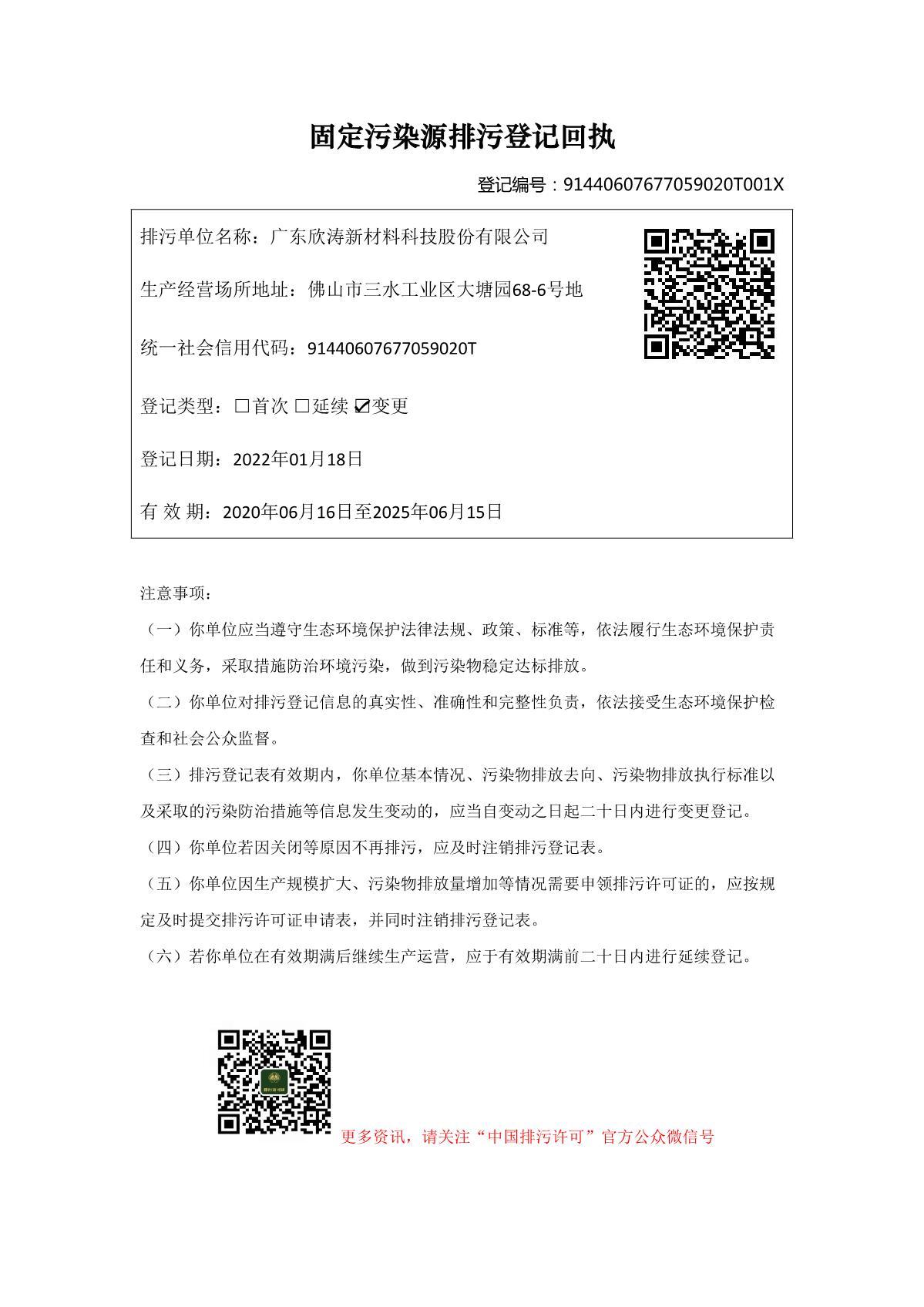

Discharge Permit

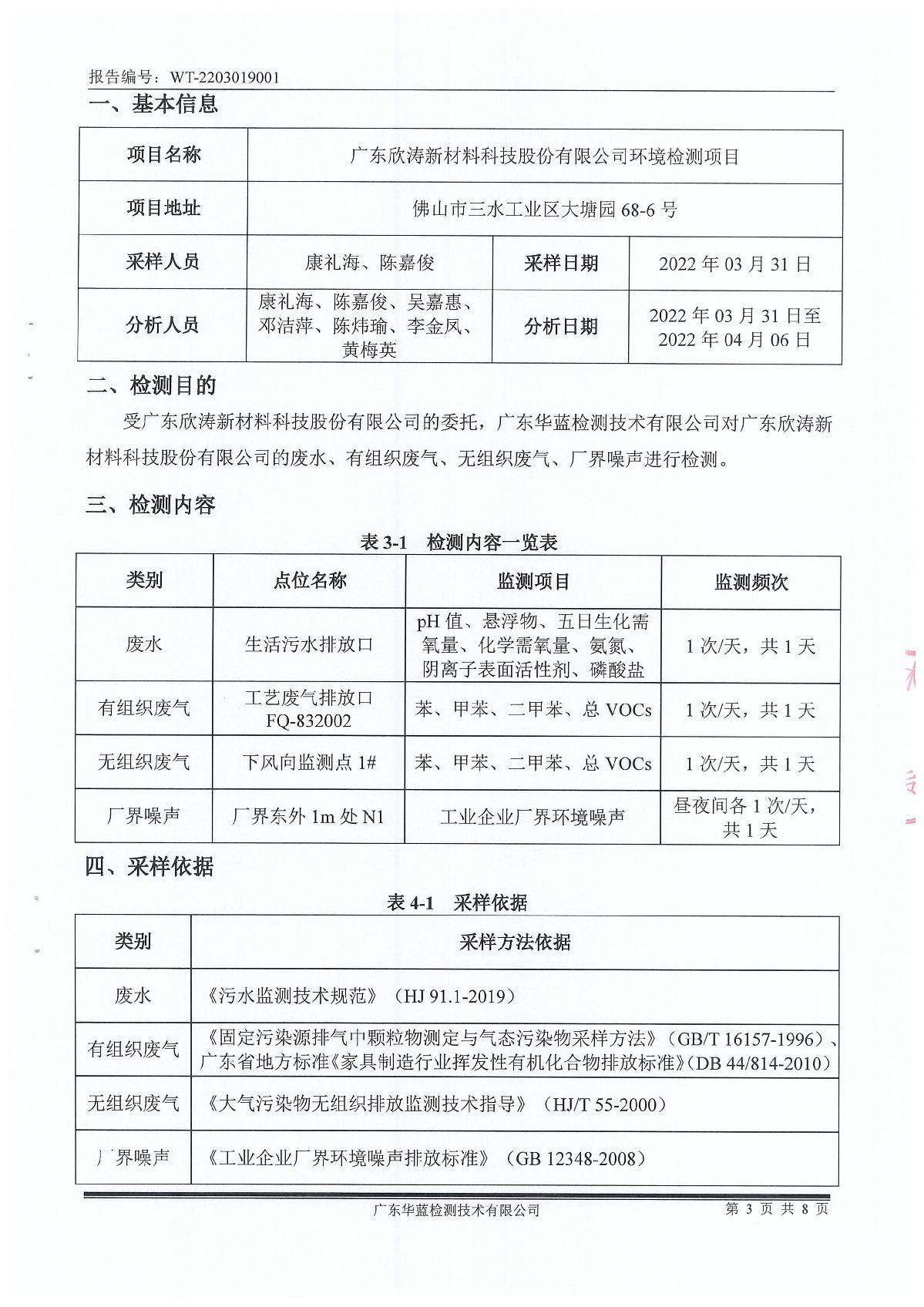

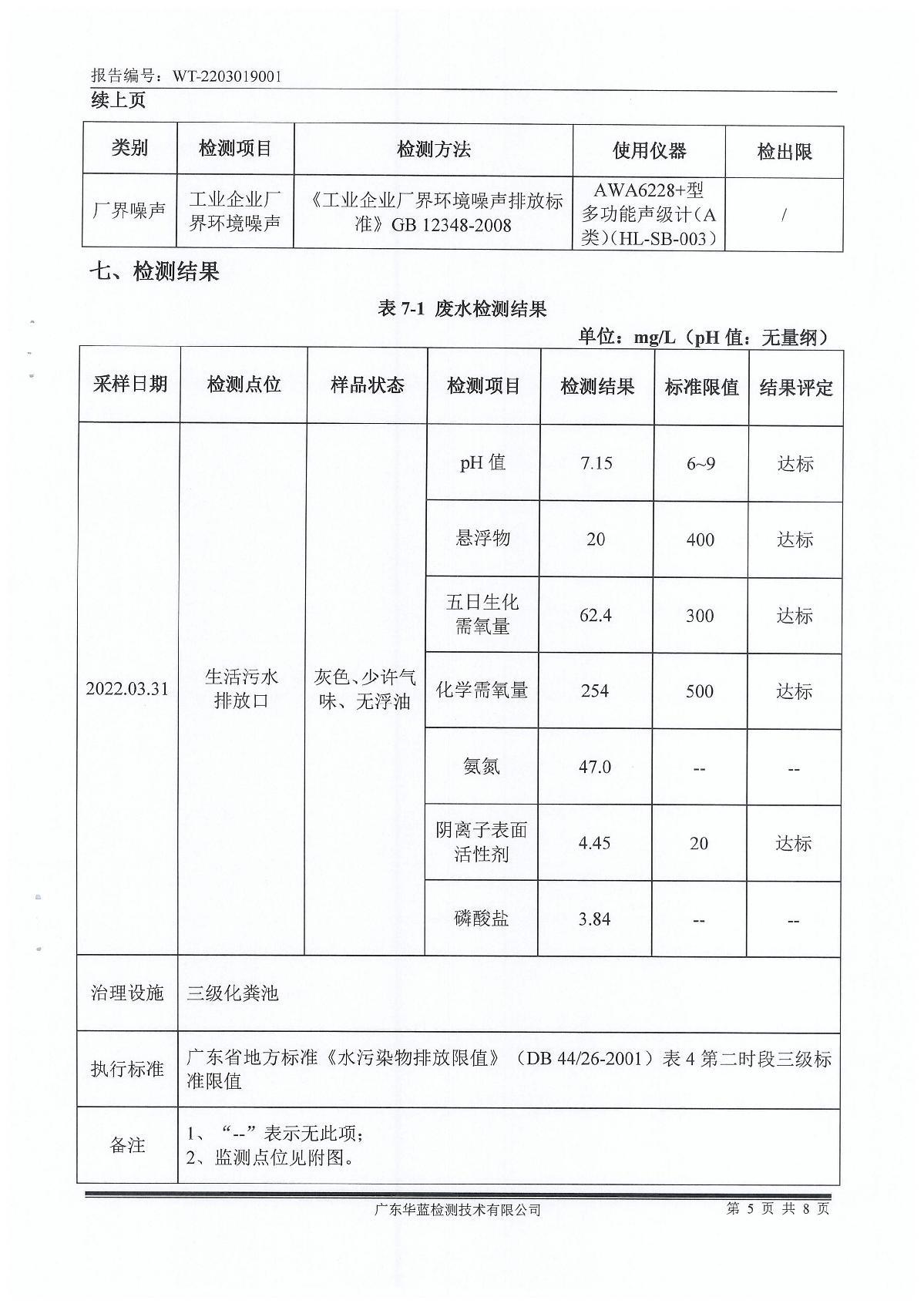

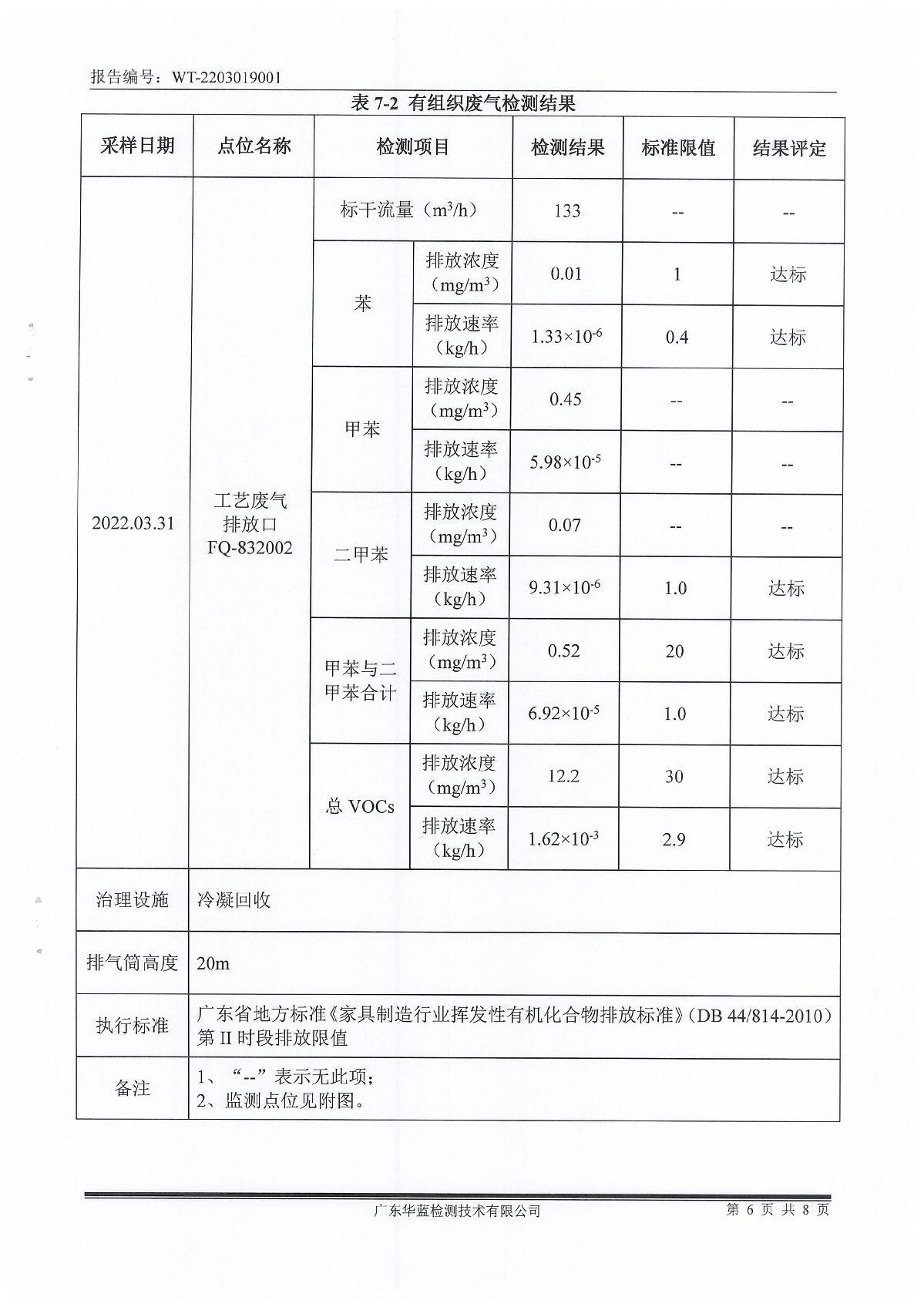

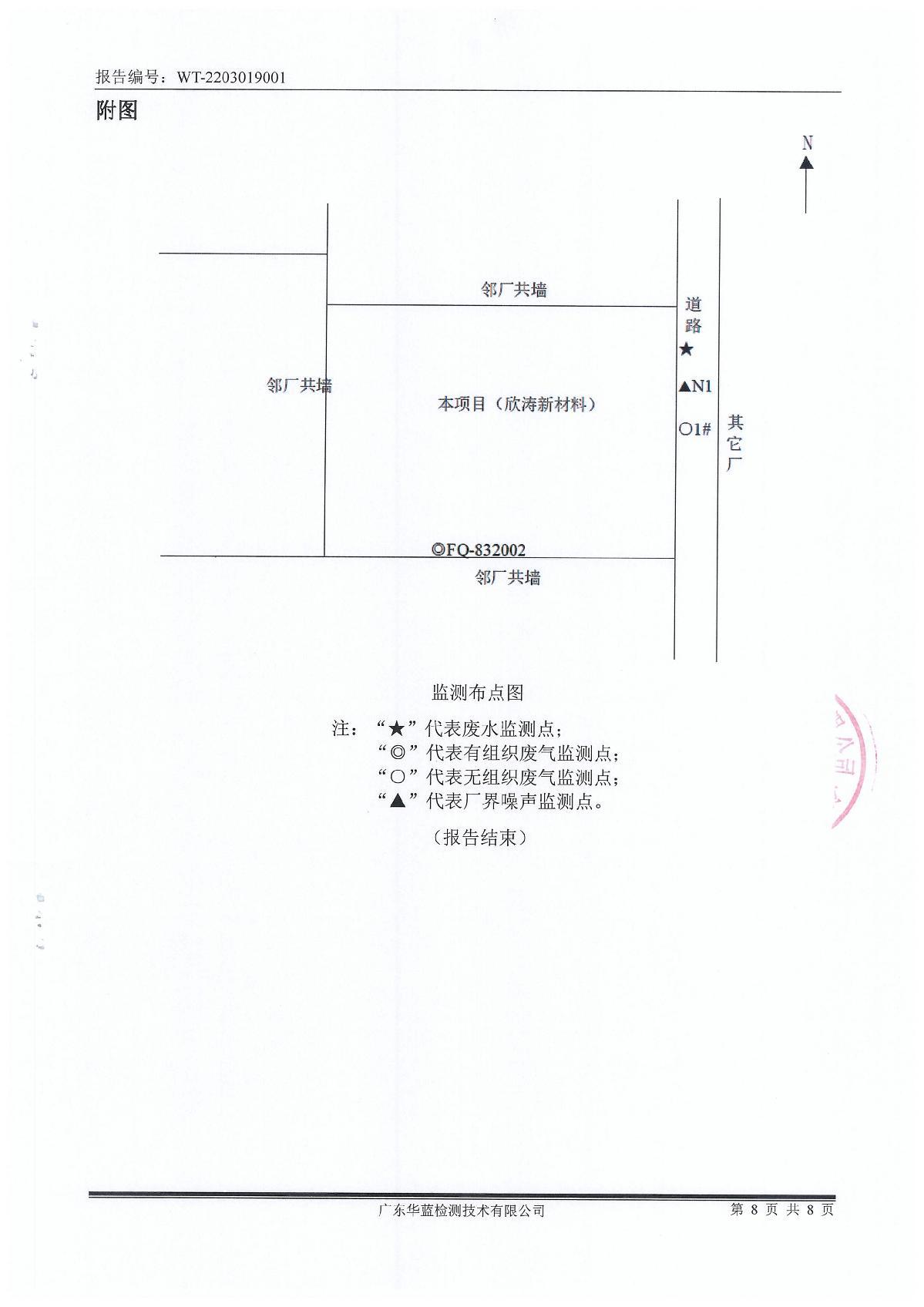

Environmental Monitoring Report

Showcase of relevant energy-saving and technological transformation projects